NOZZLE SHUT-OFF VALUES

Herzog systems ag

Swiss precision engineering combined with over 35 years experience provides you with the best shut-off system on the market today. Quality, dedication and service are why we are the world's No. 1 manufacturer and supplier of needle and bolt shut-off nozzles for the injection molding industry.

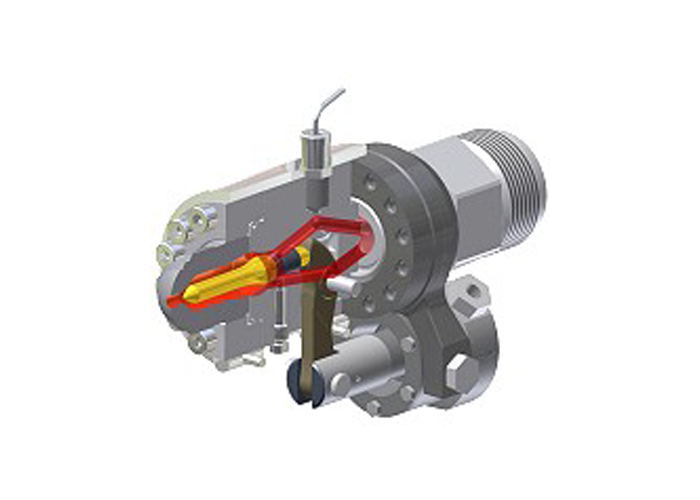

Machine bolt shut-off nozzle type BHP - pneumatic / hydraulic actuation

The pneumatically or hydraulically actuated machine bolt shut-off nozzles type BHP are used in processing of thermoplastics. In this nozzle’s favour are: Cycle time reduction, shut-off in the nozzle of the melt-stream while withdrawing or dosing. With the BHP nozzle Herzog has designed a system which allows a single through going melt flow channel. Therefore a much bigger flow channel is possible and that is responsible for a reduced pressure drop. With this single channel principle the so called “Memory effect” can be avoided. With the single channel system a cleaning of the unit is done within very short time (similar to an open nozzle).

Finds application in

Packaging, automobile and leisure industries, medicinal and electronic equipment.

Machine needle shut-off nozzle type HP - pneumatic / hydraulic actuation

The pneumatically or hydraulically actuated machine needle shut-off nozzles type HP are used in processing of thermoplastics, principally with low viscosity materials such as: PA, PPS, PE, POM,PP.

Finds application in

Packaging, automobile and leisure industries, medicinal and electronic equipment.

Machine needle shut-off nozzle type A(S) & SHP - spring operated

The spring actuated machine needle shut-off nozzle s type A(S) are used in processing of thermoplastics , principally with low viscosity materials such as: PA, PPS, PE, POM, PP.

Finds application in

Packaging, automobile and leisure industries, medicinal and electronic equipment.

Machine needle shut-off nozzle type NE (Elastomer) - pneumatic actuation

There are multiple fields of LSR applications and they are rising in importance. LSR molded parts are frequently seen in the automobile industry, home and sport components, pharmaceutical, medicine and electronic industries. Advantages of the needle shut-off nozzle type NE .

Prevents

- Silicone vulcanisation in the nozzle.

- Material leakage when dosing with a retracted injection unit.

- Material leakage while vertically injecting.

Productivity factors

- Controlled, clean shut-off of the melt stream.

- No vulcanisation in the nozzle.

- Increased process reliability and repeatability.